[ad_1]

Summary

- Studying a truck with a million miles helped Toyota improve parts for the 2022 model.

- The extraordinary durability of the driver’s seat shocked the Toyota team.

- The resin bed and V-6 engine upgrades displayed a focus on durability and efficiency.

In 2016, Toyota approached a customer from Louisiana named Victor Sheppard with a proposition: they offered to give him a brand new Toyota Tundra pick-up truck in exchange for his 2007 model. Why, would you ask?

Well, it turns out that the truck had over a million miles on the clock! To put the million miles into perspective, that’s equivalent to driving around the planet 24 times, and yet, the truck was ready to go for more. The aim of this initiative was to take that truck and see what worked so well to withstand so many miles, and what could be improved.

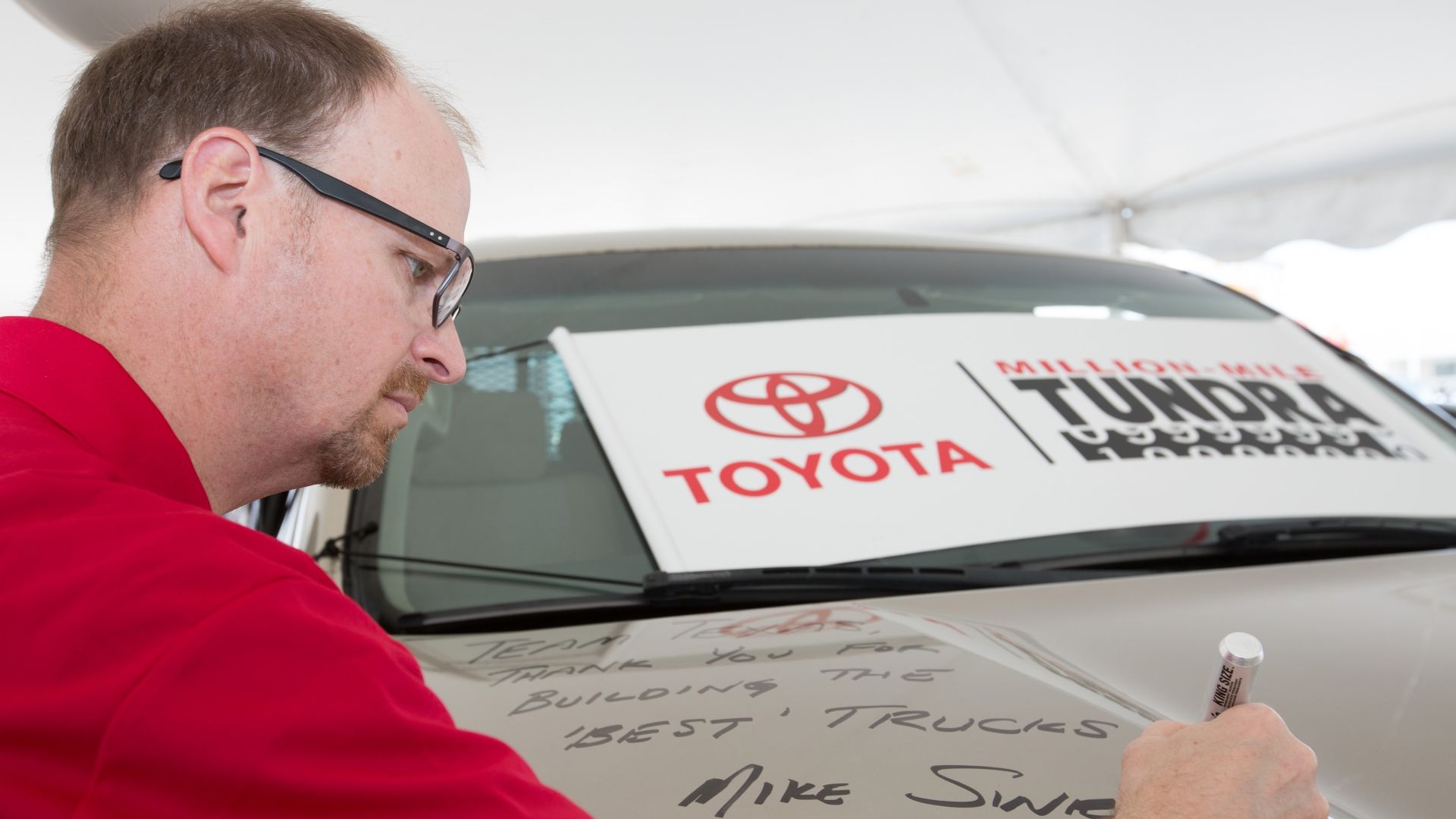

When the marketing folks asked Mike Sweers, chief engineer for Toyota trucks, if he wanted this truck that had done a million miles, he was truly intrigued. That’s why, when Sheppard agreed to make the exchange, Mike led a team of engineers at the Toyota Motor North America Research & Development Center (TMNA & RD) to study Sheppard’s pick-up.

From the interior to the bed and passing through the engine, the Toyota team thoroughly analyzed the specimen to better understand it and apply the necessary changes to the next iteration, the 2022 Toyota Tundra.

In order to give you the most up-to-date and accurate information possible, the data used to compile this article was sourced from various manufacturer websites and other authoritative sources, including Toyota and EPA.

2024 Toyota Tundra: A Comprehensive Guide On Features, Specs, And Pricing

Powerful engines and optional factory-installed TRD upgrades elevate the Tundra’s capability, while premium interior and tech promise satisfaction.

The Inside Held Up Admirably, With Only Minor Upgrades Required

Just as Sheppard’s million-mile Tundra was no ordinary truck, Sheppard was no ordinary driver. At 6 feet 6 inches and weighing 425 pounds, he was built like an NFL lineman and used this truck to make deliveries for an oil company, which led him to drive approximately 125,000 miles per year.

Naturally, that piqued Sweers’ interest in the condition of the seats. This is the reason why, instead of focusing on the engine or transmission, they decided to start by looking at something rather simpler: the front seat.

Even After Heavy Usage, The Driver Seat Remained Virtually Flawless

As Toyota employees took the truck apart and went to check Vic’s old seat, expecting to find lots of damage, they realized it was remarkably unbowed. Despite the incredibly high use, not only was the frame unbent and the foam unworn, but the seat itself, consistent with the rest of the truck, showed only light wear and tear, something amazing considering the fact that Vic had practically lived in that seat.

This finding surely made them reconsider the way of designing and testing the trucks, because the truth is that real-life usage can undoubtedly serve as a better benchmark than any laboratory test.

The Seat’s Comfort Level Was Upgraded Through Material Swapping

While the seat frame’s strength was sufficient, it proved necessary to make it lighter in order to enhance comfort and longevity.

However, introducing higher-strength materials requires caution to avoid compromising durability. Finding the right balance between strength and flexibility was crucial, taking into account not only physical dimensions but also the lifestyle of drivers like Vic.

Concerns Regarding Odometer Limits Were Addressed

Looking at Vic’s experience, Mike realized that even small parts like the sun visor matter. The wear and tear on it showed Toyota the challenges drivers face on long trips. Based on this, it was ultimately redesigned to increase its longevity and, incidentally, to enhance user-friendliness.

Additionally, the issue of odometer limits surfaced, highlighting some unforeseen consequences when setting electronic limits on mileage. Vic’s truck challenged conventional expectations, prompting a reevaluation of the established standards and the need for flexibility as some drivers go way past the usual mileage.

The Highest-Mileage Truck In The World In 2024

Getting a pickup truck past the 200,000-mile mark is a massive achievement, but to exceed 1.6 million seems almost impossible… except for one.

The Cargo Box Showed Visible Signs Of Wear From Years Of Hauling

The discussion surrounding the truck’s bed is a topic that has gotten a lot of buzz with this truck, being perhaps the most significant takeaway. Despite its million-mile journey, most parts looked surprisingly decent, except for the bed, which looked like it had taken a beating.

Moreover, upon teardown, certain areas, particularly around the deck, were identified as places where weld strength needed improvement. Vic’s line of work as a hotshot driver often took him to oil rig sites, where dropping heavy drill bits directly into the bed left noticeable marks. This highlighted the need for a bed material that could withstand such abuse.

The Resin Bed Emerged As The Optimal Solution

To remedy this problem, Sweers and his team introduced what they called a “resin bed” or, in engineering terms, the deck. Now, why did they opt for this choice?

The discussion initially revolved around the choice of materials. While aluminum provided corrosion resistance and weight savings, it lacked durability. On the other hand, high-strength steel was sturdy but susceptible to corrosion. So, which option was more suitable?

This dilemma led to the idea of a composite deck, similar to what is used in the Tacoma. Despite being more expensive, it was a hit among Tacoma customers, so it emerged as the best solution.

The composite deck presented several advantages, such as:

- Being lightweight, corrosion-resistant, and easy to repair.

- It allowed for innovative features, such as molded-in pockets for two-by-fours, catering to the diverse needs of truck owners.

- The sloped design, needed by the manufacturing process, provided an easy cleanup, eliminating the hassle of dirt buildup along seams.

They Went As Far As Throwing A V-8 Engine To Guarantee Its Endurance

Toyota torture-tested the bed before approving it for production; they dropped rocks, cinder blocks and even a V-8 engine onto the back of the Tundra. With a payload capacity of up to 1,940 pounds, the composite bed survived without a dent.

The resin bed represented a huge leap forward because it took care of the observed shortcomings in traditional bed materials. Besides, its aim was not only at enhancing durability but also to improve functionality and user experience.

History Of Toyota Pickup Trucks

We look back at the evolution of Toyota pickups over the decades and how they’ve earned a reputation for becoming some of the toughest trucks ever

Despite The Minimal Modifications Needed, The V-8 Was Swapped Out For A V-6

The 4.7-liter V-8 engine took a few victory laps around factories in North America before ending up in Ann Arbor, Michigan, where it was initially designed.

The 2007 Tundra is one of the earliest models equipped with that exact engine. Despite the fact that its owner drove around 125,000 miles per year, totaling a million miles during his ownership, the truck’s original powertrain remained largely untouched, with only minor repairs made over time, such as replacing an alternator and a water pump.

Moreover, the transmission experienced an issue with the reverse at around 770,000 miles, but otherwise it also remained the same. How often can you say that about any car or truck?

Some Components Were Upsized To Withstand The Demands Of The Improved Torque Ratings

As explained by Mike in an interview done for Pickup Truck Plus SUV Talk, Toyota’s standards are set by the Land Cruiser 70 series; they serve as a benchmark for all their trucks globally.

As they transitioned the powertrain, including the transfer case, they had to ensure that it could handle increased torque demands, especially for heavy-duty applications. This required scaling up components like the transfer case chain to accommodate higher torque outputs.

Previously, the transfer case used an inch-and-a-half chain, which was upgraded to an inch-and-three-quarters chain to meet the demands of the enhanced torque ratings. While this may seem like a minor adjustment, it significantly impacts durability and reliability under heavy loads.

Additionally, gear ratios were revised, transitioning from 4.30 to 3.31 to optimize performance without compromising durability. Contrary to popular belief, gear ratios don’t affect durability; instead, it’s the size of the ring gear and its cooling capacity that determine longevity.

Moving on to prop shafts, Sweers’ team adopted a robust design to withstand the increased torque output. By using larger shafts and high-quality materials, the risk of failures was minimized, especially under heavy loads.

Another innovation worth mentioning is the ballistic nylon skid plates, a lightweight and durable alternative to traditional steel plates.

Originally sourced from a military supplier, they offer superior protection against impacts and corrosion. Their flexibility allows them to absorb shocks without denting, ensuring lasting durability even in harsh off-road conditions.

Setting Aside Durability Improvements, The Engine Was Transitioned To A V-6 To Improve Fuel Economy

Not all the improvements that Toyota made to the third-generation Tundra were related to durability. The company also improved fuel economy by replacing the last-generation model’s V-8 with a V-6 that’s either naturally aspirated, twin-turbocharged or part of a hybrid system, and it fitted the rear suspension system with coil springs to deliver a more comfortable ride on and off the pavement.

Although the 4.7-liter V-8 proved to be a reliable workhorse, its fuel economy left much to be desired, providing a paltry 15 MPG on the street and 17 MPG on the highway – if you’re lucky, which can’t compete with the six-cylinder options.

The most intriguing part of the whole process is that, when Toyota tore down the truck, they noticed wear and tear, but not in the amount of one million miles worth.

“This is how I’d expect a Tundra with 100,000 miles on it to look, but this one has a million”, exclaimed Frank Di Maggio, the analyst at the Toyota Collaborative Benchmarking Center.

It’s remarkable that a truck used so frequently and used as it was designed could show such little wear. The key to achieving this high mileage, according to Vic, was performing monthly oil changes and regular tune-ups. It might seem excessive, but the results speak for themselves.

[ad_2]

Source link